What is/are

Fiber Optics?

Fiber Optics encompasses the transmission of light through fibers or thin

rods of glass or some other transparent material with a high refractive

index. Light that enters one end of a

fiber can travel through the fiber with very low loss, even if the fiber is

curved. Images can be transmitted, as

can data. The fiber optics itself can

be used as a sensor for variations in environmental parameters such as

temperature and pressure.

The Principle -

Total Internal Reflection

Light traveling

inside the fiber center (core) strikes the outside surface at an angle of

incidence that is greater than the critical angle. Consequently, all this light is reflected toward the inside of

the fiber without loss. Light can

therefore be transmitted over long distances by being reflected inward

thousands of times. In order to avoid

losses through the scattering of light by impurities on the surface of the

fiber, the optical fiber core is clad with a glass layer of much lower

refractive index and the reflections occur at the interface of the glass fiber

and the cladding. This avoids losses

caused by scattering of light by impurities on the fiber surface.

Bundles of several

thousand very thin fibers assembled precisely side by side and optically polished

at their ends can be used to transmit images.

Each point of the image projected on one face of the bundle is

reproduced at the other end of the bundle, reconstituting the image, which can

be observed through a magnifier. Image

transmission by optical fibers is widely used in medical instruments for

viewing inside the human body and for laser surgery, in facsimile systems, in

phototypesetting, in computer graphics, and in many other applications.

Instrumentation:

Optical fibers are

used in numerous sensing devices, ranging from thermometers to gyroscopes. The transmitted light is sensitive to

environmental changes, including pressure, sound waves, and strain, as well as

heat and motion. The fibers can be

especially useful where electrical effects could make ordinary wiring useless,

less accurate, or even hazardous.

Fibers have also been developed to carry high-power laser beams for

cutting and drilling. Petroleum

applications include sensors.

Communication:

In addition to

sensing environmental variations, fiber optics can be used to transmit the

measurements to the surface. Because

the information-carrying capacity of a signal increases with frequency, the use

of laser light offers many advantages.

Fiber-optic laser systems are being used in communications

networks. Long distances (100 km) can

be achieved before signal repeaters are needed to regenerate signals.

History of

Fiber Optics

While it may not be of critical need to you in your

day-to-day operations, the following chronology is light and informative

reading, documenting the exponentially accelerating technology.

·

Alexander Graham Bell patented an optical telephone

system, the Photophone, in 1880. Since

then, technologies that would make optical transmission possible have

developed.

·

In the 1840s, Daniel Collodon and Jacques Babinet showed

that light could be guided along jets of water for fountain displays.

·

British physicist John Tyndall popularized light guiding

in a demonstration he first used in 1854, guiding light in a jet of water flowing

from a tank.

·

By the 1900s, inventors realized that bent quartz rods

could carry light, and patented them as dental illuminators

·

During the 1920s, John Logie Baird in England and C.W.

Hansell in the United States patented the idea of using arrays of hollow pipes

or transparent rods to transmit images for television or facsimile systems.

·

In a 1930 paper, Heinrich Lamm demonstrated image

transmission through a bundle of optical fibers. He reported transmitting the image of a light bulb filament

through a short bundle.

·

In 1951, Holger Mřller Hansen applied for a Danish patent

on fiber-optic imaging. It was denied, citing the Baird and Hansell patents.

·

In 1954, A. van Heel (Technical University of Delft) and

H. H. Hopkins and N. Kapany (Imperial College) separately announced imaging

bundles in Nature. These bundles

could not carry light far. All earlier

fibers were "bare," with total internal reflection at a glass-air

interface. van Heel covered a bare

fiber of glass or plastic with a transparent cladding of lower refractive

index. This protected the total

reflection surface from contamination, and greatly reduced crosstalk between

fibers.

·

L. Curtiss (University of Michigan) developed glass-clad

fibers while working on an endoscope to examine the inside of the stomach (with

physician B. Hirschowitz, and physicist C.W. Peters).

·

W. Hicks, (American Optical Co.) made glass-clad fibers at

about the same time, but his group lost a bitterly contested patent battle.

·

By 1960, glass-clad fibers had attenuation of about one

decibel per meter. This was adequate

for medical imaging, but much too high for communications.

·

Telecommunications engineers were seeking more

transmission bandwidth (e.g., A. Reeves, at Britain's Standard

Telecommunications Laboratories).

·

The invention of the laser in 1960 brought more converts.

·

Serious work on optical communications accelerated with

introduction of the continuous wave helium-neon laser.

·

By 1965, it was clear that major technical barriers

remained for both millimeter-wave and laser telecommunications. Millimeter waveguides had low loss, although

only if they were kept precisely straight; developers thought the biggest

problem was the lack of adequate repeaters.

Optical waveguides were proving to be a problem. S. Miller's group at Bell Telephone

Laboratories was working on a system of gas lenses to focus laser beams along

hollow waveguides for long-distance telecommunications.

·

Optical fibers were shown to be analogous in theory to

plastic dielectric waveguides that were used in certain microwave

applications. In 1961, E. Snitzer

(American Optical Co.) and W. Hicks (Mosaic Fabrications, now Galileo

Electro-Optics) demonstrated the similarity by drawing fibers with cores so

small that they carried light in only one waveguide mode.

·

C.K. Kao (Standard Telecommunications Laboratories)

evaluated fiber attenuation. He

collected samples from fiber makers, and carefully investigated the properties

of bulk glasses. His research convinced him that the high losses of early

fibers were due to impurities, not to silica glass itself.

·

Kao and G. Hockham conceived methods for long-distance

communications over single-mode fibers (with fiber loss below 20 decibels per

kilometer) - a glass core about three or four microns in diameter, clad with a

coaxial layer of another glass having a refractive index about one percent

smaller than that of the core. Total

diameter of the waveguide is between 300 and 400 microns. Surface optical waves are propagated along

the interface between the two types of glass – flexible but strong.

·

F. F. Roberts, at the British Post Office Research

Laboratory raised a new research fund of 12 million pounds to study ways to

decrease fiber loss.

·

At the Corning Glass Works (now Corning Inc.), R. Maurer,

D. Keck and P. Schultz started with fused silica, a material that can be made

extremely pure, but has a high melting point and a low refractive index. They made cylindrical preforms by depositing

purified materials from the vapor phase, adding carefully controlled levels of

dopants to make the refractive index of the core slightly higher than that of

the cladding, without raising attenuation dramatically.

·

In September 1970, they announced they had made

single-mode fibers with attenuation at the 633-nanometer helium-neon line below

20 dB/km.

·

In the same year, Bell Labs and a team at the Ioffe

Physical Institute in Leningrad made the first semiconductor diode lasers able

to emit continuous waves at room temperature.

Over the next several years, fiber losses dropped dramatically, aided

both by improved fabrication methods and by the shift to longer wavelengths

where fibers have inherently lower attenuation.

·

Early single-mode fibers had cores several micrometers in

diameter, and in the early 1970s that bothered developers. They doubted that it would be possible to

achieve the micrometer-scale tolerances needed to couple light efficiently into

the tiny cores from light sources, or in splices or connectors. Not satisfied

with the low bandwidth of step-index multimode fiber, they concentrated on

multi-mode fibers with a refractive-index gradient between core and cladding,

and core diameters of 50 or 62.5 micrometers.

The first generation of telephone field trials in 1977 used such fibers to

transmit light at 850 nanometers from gallium-aluminum-arsenide laser diodes.

·

Those first-generation systems could transmit light

several kilometers without repeaters, but were limited by loss of about 2 dB/km

in the fiber. A second generation soon appeared, using new InGaAsP lasers which

emitted at 1.3 micrometer, where fiber attenuation was as low as 0.5 dB/km, and

pulse dispersion was somewhat lower than at 850 nm. Development of hardware for

the first transatlantic fiber cable showed that single-mode systems were

feasible, so when deregulation opened the long-distance phone market in the

early 1980s, the carriers built national backbone systems of single-mode fiber

with 1300-nm sources. That technology has spread into other telecommunication

applications, and remains the standard for most fiber systems.

·

However, a new generation of single-mode systems is now

beginning to find applications in submarine cables and systems serving large

numbers of subscribers. They operate at 1.55 micrometers, where fiber loss is

0.2 to 0.3 dB/km, allowing even longer repeater spacings. More important,

erbium-doped optical fibers can serve as optical amplifiers at that wavelength,

avoiding the need for electro-optic regenerators. Submarine cables with optical

amplifiers can operate at speeds to 5 gigabits per second, and can be upgraded

from lower speeds simply to changing terminal electronics. Optical amplifiers also are attractive for

fiber systems delivering the same signals to many terminals, because the fiber

amplifiers can compensate for losses in dividing the signals among many

terminals.

Excerpted and modified from Fiber Optics

Technician's Handbook, by Jim Hayes, Delmar Publishers, Albany, New York

and Laser Focus World (November 1994).

See also City of Light: The Story of Fiber Optics, Oxford

University Press, New York, 1999. (ISBN 0-19-510818-3) and http://www.sff.net/people/Jeff.Hecht/history.html.

Petroleum Applications of Fiber Optics

(Excerpted from Wright, P.J., “Optical fiber's gigabit bandwidth, 200 km range attractive for subsea work.” Offshore Magazine (May 2000).

Up until now, optical fiber use in the petroleum

industry has been somewhat limited to applications supporting technology that

cannot function with "standard" electrical communication (to provide

communication where high levels of electrical noise prevent the use of

copper-based communication), for direct access to optical sensors (subsea and

downhole) and for communication with sensor systems providing either continuous

real-time data, or information at data rates higher than can be supported by

existing electrical communication.

Fiber optics continues to provide a flexible enabling technology for

future subsea oilfield development

“The resulting growth in control systems

functionality and update rates is pushing the need for increased communication

bandwidth, and the need for more flexible and fault tolerant communication

systems using bus architectures. The

search for improved profitability is also driving the development of new and

improved subsea and downhole sensors and sensor arrays.”

Platform-to-Platform Communications

Until 1996, fiber optics were used offshore only

for communication between adjacent platforms.

The Dunbar Platform is operated from the North Alwyn Platform, 22 km

away. The fiber optic link is provided by two continuous power umbilicals

connecting the platforms. Nowhere in this system is there access to the fibers

subsea.

Subsea Machinery

The electrical noise environment around new subsea

production techniques (e.g. subsea separation, multiphase pumping), and the

power umbilicals that supply them, are problematic for conventional electrical

communication and have driven the move to inherently noise immune, fiber optic

communication configured for the modular offshore installation.

Well Diagnostics

In the North ETAP development, Shell has

permanently installed downhole, passive optical sensor heads that were tied

back to their drive and diagnostics system located on the Marnock platform 25

km from the furthest well.

Umbilical Cross-Section

“Some recent deepwater development programs have

realized significant financial advantages using optical fiber in place of

copper. Studies have shown that the

forecast umbilical construction and installation cost show significant CAPEX savings

particularly for deepwater installation.

Construction savings arise from the reduction in cross-section in the

umbilical core that comes from removal of multiple copper communication lines,

and their replacement by one or two fiber elements. This saving is then compounded by the reduced amount of armoring

needed for the smaller core.

“Reduced installation costs come from the decreased

cross-section and weight per unit length of the umbilical, and therefore the

maximum length that can be installed in one piece. Where the increase in length

results in the removal of, or reduction in, the number of umbilical mid-span

joints, then the installation costs are reduced even further. With the

umbilical costs being one of the main drivers in overall program am economics,

the significant cost reductions that may be possible with a fiber optic option

can result in the decision to develop a marginal field.”

Critical Technology

Throughout these advanced programs, the critical

technology was the development of the first low optical loss wet mate fiber

optic connector. Without this, the modular installation of these and many other

systems could not have moved ahead.

Communication

Historically, electrical communication for subsea

control and data acquisition has been limited to 1,200 bit/sec, with anything

up to 400 bit/sec being used for control system housekeeping functions.

Consequently, the update rate for production related data has been slow by

normal industrial standards, where typically Ethernet type systems are now

being employed. This is particularly noticeable where a number of subsea

control modules (SCM's) are interrogated sequentially through a topside control

system that uses a single modem. By comparison, a single digital telephone

conversation requires 64 Kbit/sec.

Fault Tolerant Systems

“Fault tolerant systems will feature heavily in the

expansion into ultra-deepwater, as remotely operated vehicle (ROV) configurable

and retrievable equipment become standard.

This will include modular control systems, ROV installable valves and

chokes, and the position sensors associated with them, as well as specialized

sensors for fiscal metering and multi phase flow measurements, directly

addressed through the optical fiber.”

“The Gulf of Mexico has just seen the installation

of the first high bandwidth (2.5 Gbit) telecommunications cable solely for the

use of offshore platforms. This "fiber web" link installed by

PetroCom, for the first time provides the opportunity to directly control or

monitor the performance of a subsea (or downhole) system from the office

desk. This technology currently offers

more reliable, versatile, and cost-effective, communication than the existing

cellular and microwaves options. The

Fiber Web system runs from Freeport, Texas via seven offshore platforms to

Fourchon, Louisiana, and completes the ring on land through New Orleans and

Houston.”

Subsea Production

Multiphase pumps, and/or subsea separation systems,

which themselves will benefit from a high bandwidth controls and condition

monitoring system, and where high power electrical motors are included, the

noise immune performance of optical fiber simplifies the prevention of data

corruption on the communication lines.

Norsk Hydro installed the Troll Pilot subsea

separator system late last year. This system, built by ABB Offshore, includes a

2 MW pump to pressure boost the wastewater for re-injection. All communication

on this system is by optical fiber.

Petrobras has developed a deepwater (1,000 meters

water depth) compatible multiphase pump that communicates with the surface over

a fiber optic link built into the power umbilical to the motor. A number of other separator and multiphase

pump programs such as Total's Nautilus multiphase pump program, and the CoSWaSS

(configurable subsea water separation system) joint industry project have also

concluded that fiber optic communication is necessary for secure, error-free

communication.

Technology to produce slim-line hydrocyclones,

capable of installation in a wellbore, is under development. The pumps needed to dispose of wastewater through

a lateral, or for production boost already exist. Control and monitoring technology for these systems will require

environmentally robust, high bandwidth noise immune communication, using

downhole fiber optic cables and connectors.

The various produced fluids will need high bandwidth sensors such as

photo acoustic oil-in-water sensor technology, which are already in development

for oil-in-water measurement for production optimization. Effective equipment wear monitoring will be

necessary to allow scheduled replacement, and minimize rig activation costs.

Sensing Applications

Optical fiber offers the next major step change in

sensor technology for the subsea and downhole arenas. Optical fiber sensors can

he used to measure effects such as:

·

Position and movement with fiber gyroscopes

·

Acoustics with fiber hydrophones

·

Strain in "smart structures"

·

Chemicals and reactions

·

Electrical supply characteristics.

Fiber will be used to provide high bandwidth,

electrical noise immune, environmentally stable communication with multiplexed

sophisticated subsea and downhole equipment.

Optical fiber will also provide communication to a range of discrete

passive optical sensor heads, measuring temperature, pressure, flow, and vibration.

The fiber itself can be used as a distributed

sensor, using either the Brillouin or Raman scattering effects, inherent in all

fiber. It is currently possible to

measure temperature and strain over fiber lengths of up to 30 km. This technology, already in use to measure

temperature distribution in land-based wells, can also be used to monitor

continuous pipeline temperature from the well to the platform and provide early

warning of waxing or hydrate formation, or monitoring of pipeline temperature

change during a shut-in.

“Discrete multiplexed sensor elements can be

written directly onto glass fiber using an intense UV light source. These are

known as Fiber Bragg Gratings (FBG), and reflect only the frequency of light

which matches the grating pitch, so any parameter need only cause a change in

length of a fiber section containing a grating to cause a shift in the

reflected wavelength.”

It is possible to construct networks of Bragg

gratings to measure temperature, pressure, strain, vibration, and acoustic

signals over a single fiber. The change

in reflected wavelength, indicating the change in an environmental parameter,

can be detected by coupling a "white" light source onto the

fiber. The reflected signals are for

any wavelength shift from a calibrated value.

The source and detection equipment can be located

some distance from the well, and linked by optical fiber and fiber optic

connectors. Temperature, pressure, and

other parameters can be accurately recorded.

Optical fiber can also be used to sense passive,

discrete sensor elements. These often include a cavity whose length is modified

by the parameter of interest, which results in a change in the optical signal

picked up by the optical fiber. Shell

ETAP’s program uses this type of detection - FOWM (fiber optic well

monitoring).

“The move into ultra-deepwater brings with it the

need to implement structures using lightweight composite and smart

materials. Many composite material

manufacturers are experimenting with Bragg Grating encoded glass fiber bedded

directly into the composite matrix, so that the gratings form a sensor net

capable of measuring loading in any direction of interest. This "smart composite" material

technology is being investigated by the offshore industry to support the

construction of many lightweight structures.”

Examples include drilling and production risers as well as composite

tension legs and tethers.

Environmental Tolerance

In comparison to electrical equipment,

survivability in the subsea and downhole environments, with contact with water

is superior.

The glass fiber will tolerate temperatures above

1,000oC. Polyamide coated

cable assemblies will survive 600oC. The fiber should be protected inside a hermetically welded,

buffer gel filled tube. This tube can

be housed within a second hermetically welded tube with support wires. The final tube diameter is ~1/4-in. in

diameter, and this can be used with production tubing.

Cost

Currently, the cost of single mode fiber (about 5

cents/ft) and a twisted shielded pair copper (30 cents/ft for 18AWG twisted

shielded pair cable) are cost comparable, and it should be expected that the

pricing would be even more favorable.

Strength

Under tension optical fiber has strength equivalent

to steel. There is little resistance to

shear and careful handling is required when the fiber is not protected in a

cable or jumper. As a cable element,

the fiber element can be handled with the same equipment and techniques as any

other element that is being built into an umbilical.

Hydrogen Darkening

Hydrogen ions, naturally present at low partial

pressures or from more corrosion, or a cathodic protection system, can be

absorbed by glass fiber. This causes

increased attenuation. This effect is

only of interest where long lengths (kin) of fiber are involved.

Properly designed umbilicals keep out hydrogen

since they are in hermetically welded steel or copper tube, filled with a

buffer gel that has hydrogen adherence properties. Alternatively, the fiber can be run through a non-corrosive

jumper, such as thermoplastic hose.

Carbon coated fiber can also be used.

A reference is Lemaire, P.: “Reliability of Optical

Fibers Exposed to Hydrogen: Prediction of Long-Term Loss Increases,” Optical

Engineering 30(6) (June 1991) 780-789.

More on

Optical Sensors

(Excerpted from Williams, G.:

“Optical sensing coming of age in production monitoring.(Petroleum Production

Engineering” Offshore Magazine (January, 1999).

Background

Probably the first commercial fiber optic pressure

sensor was developed through a joint industry program between Norsk Shell and

Alcatel Kabel Norge with BP Norway and Norsk Hydro as co-sponsors to offer

permanent downhole pressure and temperature measurement and to be capable of

operating in HP/HT environments (120 to 150oC).

What is an Optical Sensor?

It is a micro-machined silicon oscillator that is

activated and read optically through a single fiber. The fiber's resonant frequency varies with the pressure and

temperature downhole. It is practically

insensitive to fluctuations in signal attenuation and can be operated remotely. Over five of these systems have so far been

installed.

A system developed by Sensor Highway of Andover, UK

deploys optical sensors using a conduit concept. This allows thin filament sensors to be placed in the well using

fluid drag and has certain intrinsic advantages.

·

Downhole splices in the optical fiber are not required

·

Sensors can be installed at any time, even after

completion

·

Faulty sensors can be replaced or upgraded sensors can be

installed during the life of the well

·

Sensors can also be "buffered" using specially

formulated fluids that are placed in the conduit.

Optical

sensors’ inherent properties also provide:

- High sensitivity

- Electrical

passiveness

- Wide dynamic range

- Multiplexing

capability

Temperature

Measurement:

The Distributed Temperature Sensor (DTS) was

developed for short range (monitoring 1.5 km) to long-range implementations up

to 30 km. Distributed temperature

sensing can be used to provide a real-time thermal profile along the entire length

of the well, enabling optimal inflow conformance through the detection of any

thermal event. Temperature data are

measured at every point along the line.

Laser light pulses are generated by the DTS and launched into the

optical fibre sensor. As the light pulse encounters temperature features along

the fibre the pattern of back-scattered light returning to the DTS changes.

Advanced signal processing within the DTS retrieves the temperature profile of

the fibre from the backscatter signal. Unlike

conventional instrumentation, the fibre optic system serves as both a sensor

and the means of transmission. The

Sensa distributed temperature system measures temperature along the whole

length of an optical fibre in real time.

With photons traveling at the speed of light through the fibre,

measurements can be made along the complete well without an intervention.

A surface laser sends a light pulse down the fibre

and a computer analyzes the back-scattered light from every meter interval of

the fibre – from the surface to well bottom and back. Temperature is calculated for

every meter along the fibre to an accuracy of 0.1°C and a resolution of 0.1°C.

Installation of Sensa’s fibre

optic distributed temperature system takes place while the well is being

completed using a special hydraulic installation technique licensed from

British Telecommunications plc.

The

temperature monitoring of complete well profiles in real time allows a thermal

signature of the well to be determined.

Subsequent changes in temperature can be used to identify and monitor:

- Flow profiling

- Injection monitoring

- Flow behind casing

- Gas lift efficiency

- Fracture zones

- Casing leaks and

channels

- Lost circulation

zones

- Cement top

identification

- Cement squeeze

validation

- Steam breakthrough

- Steam channeling

These data can be correlated with

information acquired on the surface - including flow rates and water cut - as

well as from openhole logs and tester data - resulting in qualitative and

quantitative information about the changes that are occurring downhole.

As indicated, distributed temperature

is measured by sending a pulse of laser light down the optical fibre. Molecular

vibration (which is directly related to temperature) creates weak reflected

signals. The reflected signal is detected in the surface read-out unit and

converted to values of temperature at 1-meter intervals along the fibre and

well. The temperature data can be displayed on-site, stored for later analysis

or transmitted in real-time via modem or scada/modbus links.

The distributed temperature system has two modes of operation, single

ended (SE) and double ended (DE).

Systems are designed and configured according to particular

applications.

Typical specifications are shown

below.

|

Spatial Resolution |

1.0

meters or 2.5 meters depending on the model |

|

Accuracy |

+/-

0.1oC +/- 1.0oC depending on the model |

|

Resolution |

+/-

0.1oC +/- 0.5oC depending on the model |

|

Light

Source |

Pulsed

Class 3 Laser |

|

Optic

fibre |

Multi-mode |

|

Temperature

Analysis |

Raman

back scattering |

|

Temperature

range |

-40° to +300° C |

|

Single

ended accuracy |

+/-

0.5° C |

|

Single

ended resolution |

+/-

0.5° C |

|

Double

ended accuracy |

+/-

0.1° C |

|

Double

ended resolution |

+/-

0.1° C |

|

Depth

increments |

1

meter |

|

Time

increments |

15

minutes plus |

|

Operating

Length/range |

<12

km |

Principles of Operation

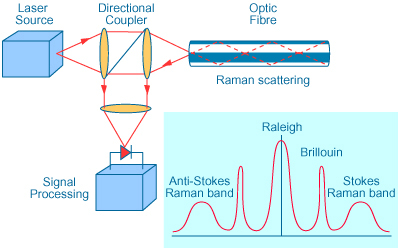

DTS with optical fibers is based on optical time-domain reflectometry. A pulsed laser is coupled to an optical fiber that is the sensing element. The light is backscattered as the pulse propagates through the fiber owing to density and composition as well as to molecular and bulk vibrations. A portion of the backscattered light is guided back to the light source and split off by a directional coupler to a receiver. Under ideal conditions the intensity of the backscattered light decays exponentially with time. As the speed of the light within the fiber is known, the distance that the light has passed through the fiber can be derived from the time along the decay curve. (See Figure 1).

Figure 1. Schematic operation of a fibre optics

device.

The backscattered light includes

different spectral components; Rayleigh, Brillouin and Raman bands. The Rayleigh component is independent of

temperature but is useful in identifying breaks and inhomogeneities along the

fiber. This is the main tool used by

the telecommunications industry to check the condition of optical fiber

communication links. The Raman spectral

band is caused by thermally influenced molecular vibrations. These are naturally occurring phenomena in

glass as well as in fluids, gases and solids.

The Raman spectral band can be used to obtain information about

distribution of temperature along the fiber.

The Raman backscattered light has two components, Stokes and

Anti-Stokes, one being only weakly dependent on temperature and the other being

greatly influenced by temperature. The

relative intensities between the Stokes and Anti-Stokes are a function of

temperature at which the backscattering occurred. Therefore, temperature can be determined at a remote point in the

optical fiber (wave form is inset in Figure 1).

Precautions

It is crucial to avoid excessive

build up of either intrinsic or extrinsic energy losses in the optical

fiber. Intrinsic energy losses arise

from the scattering and absorption of the light in the optical fiber

medium. Connectors generate extrinsic

energy losses as do field splices, and fibers that have tight bends and

excessive heat or mechanical damage.

Excessive losses will lead to a gradual degradation in measurement range

or complete loss of signal in the extreme case.

Hydrogen Attenuation:

It has been recognized since

1982 that there are absorptive losses associated with hydrogen that is

dissolved in silica glasses. Due to its

small size, the H2 molecule, which may be present around an optical

fiber, can readily diffuse into the central light guiding region of the

fiber. Early accelerated laboratory

tests found that loss increases could occur due to hydrogen, which either

originated from polymeric materials or from galvanic corrosion cells in subsea

cables. Problems of this sort have been dealt with by:

(1)

Altering the fiber dopant composition

(2)

Redesigning the fiber cables to avoid the possibility of H2

generation, and

(3)

Using hermetic coatings to block the diffusion of any

hydrogen that might be present in the cable.

However, even when the problems associated with large short term losses are solved, there still remains the issue that there might be small but significant long-term loss increases due to the trace levels of hydrogen that can remain in fiber cables. Laboratory experiments to date suggest that with a well-manufactured optical fiber and good hermetic coating, ingress of hydrogen into the optical fiber only occurs at temperatures greater than 572 °F (300°C). At temperatures below this value, existing coating technology is capable of limiting hydrogen ingress to a level that does not result in fiber degradation. Fiber degradation is evidenced by a significant increase in attenuation through wave-guide darkening.

Liquid Ingress into the Fiber:

The ingress of liquids into

optical fibers can lead to both increases in fiber attenuation and eventual

mechanical failure of the fibers.

Fluids that pass into the fibers create absorptive losses in the wave guide

and create mechanical stress in the fiber, which leads to micro-bending

effects. Water is extremely damaging

to optical fibers. Water ingress,

if permitted will extend any surface cracks that may be naturally occurring in

the fiber surface and these will be elongated by a stress cracking

process. The diameter of the optical

fiber will be reduced to the point where it cannot support its own weight and

failure will occur. The use of hermetic

coatings in situations where the optical fiber is likely to be exposed to water

has been the traditional means of combating this problem.

Micro-bending:

Optical fibers also suffer

increased extrinsic energy losses due to micro-bending effects. Large bends of cable and fiber are

macro-bends and small-scale bends in the core-cladding interface are

micro-bends. Macro-bends rarely create

difficulties when optical fibers are deployed downhole. However, care is necessary to avoid forming

micro-bends particularly at temperatures in the region of 482 °F (250°C). Micro-bending can occur when stresses are

built up in the fiber coatings as either the fiber is heated or cooled. Probably, cyclical heating and cooling

offers the greatest challenge for optical fibers in respect to micro-bending

losses. Tests performed for Canadian

huff and puff operations indicate that there is severe micro-bending when the

fiber is returned to ambient reservoir conditions after being exposed to

temperatures as high as 644 °F. Further

optical fiber coating development will be required to take measurements

accurately across the full range of 86° - 644 °F.

In 1999, Carnahan et al.,

stated:

“Disadvantages of the fiber optic system when compared to the thermocouple bundle is the higher cost associated with the data acquisition system. System accuracy and resolution is a function of response time and several minutes are required to reach accuracy and resolution of 0.5 °F and 0.2 °F respectively. Finally, the relative fragility of the optical fiber can be a problem before it is placed in the control line.”

Installation

Installation of the Distributed

Temperature Sensor is “simple” - the well is equipped with a 1/4 inch O.D.

control line. This can be installed

either outside or inside casing/liners or screens. Specially coated optical fibre is then pumped into the control

line and connected to an opto-electronic surface read-out unit.

Standard oilfield procedures are used to equip the completion with the

control line. This can be either part

of a new well design or as part of a work-over schedule. Optical fibre is then placed into the

conduit using a hydraulic system under license from British Telecommunications

plc

The

apparatus for installation of the optical fibers is protected by US Patents

5022634 and 5199689 (and corresponding foreign patents). It has been manufactured under license from

British Telecommunications plc and is the property of Sensor Highway Ltd.

Installation

of Sensa’s distributed temperature fibre takes place either while the well is

being completed or once the completion is finished using a special hydraulic

installation technique licensed from British Telecommunications plc.

Unlike

permanently installed electrical sensors, the system has a high reliability

under extreme conditions and unlike conventional logging methods, there is no

risk to the well from the intervention or loss of production while the log is

being run.

The optic fibre is pumped around

a 1/4-inch control line that is installed during the well completion, or

workover. Over

10,000 meters of fibre have been successfully installed in control line in a

single well. The

control line can be installed either as a single line, or as two lines with a

Sensa designed Turn Around Sub at the bottom allowing both ends of the fibre to

be connected to the surface electronics. Double ended mode will give a more accurate temperature

measurement and is preferred if analysis of flow contribution over the

reservoir is required.

Figure 2. Distributed Temperature Implementation

To recap, devices

of this sort can:

·

Reduces production logging intervention and lost or

deferred oil production.

·

Simple & highly reliable monitoring tool that will

out-live the well.

·

Provides real-time TD-to-well head measurement of

temperature at 1 meter intervals with one compact optical fibre cable.

·

One sensor system provides information on in-flow

characteristics, gas breakout, artificial lift equipment and mechanical

integrity.

·

Sensor can be replaced if necessary without intervention.

Completion Configuration

Areas

that need to be considered for integration of the Sensa system with the

completion include:

·

Wellhead barriers provided by

Sensa to suit different environments and legislative requirements.

·

Wellhead modifications to

facilitate passage of the control line through the wellhead.

·

Tubing hanger modifications to

facilitate passage of the control line through the tubing hanger.

·

Clamps/straps are required to

protect the control line. Equipment ranges

from specialized clamps for protecting the control line on the outside of

horizontal gravel-pack screens to simple stainless steel bands to anchor the

control line to the outside of tubing or casing of shallow vertical wells.

·

On-off disconnect unit is required

if the completion is to be run in more than one trip. The on-off disconnect protects and orientates the two control

lines in the upper and lower portions of the completion.

·

Packer penetrators to allow

passage of the control line through packers.

·

Turnaround sub to allow smooth

controlled turn of the control line at the bottom of the instrumented

completion.

The

distributed temperature system surface readout has been designed as a modular

unit to provide up to 24 optical sensing channels. Each channel is dedicated to a particular temperature sensing

optical fibre that can be up to 12 km in length. Typically one channel is dedicated to a single well however

shallower vertical wells can be joined into one loop by running the fibers in

series down each well until the total length limitation has been reached.

The

distributed temperature data can be seamlessly integrated into existing DCS,

PLC or SCADA type systems for production control and monitoring. Working with

state of the art techniques including web-based delivery systems allows the

information to be placed at the desks of the people who need to make the

decisions.

Thermal

simulation models are used to match measured profiles with production

conditions and so provide valuable information on changing production

conditions without having to run a production log. Reservoir

Additional

references include:

1.

Osato, K., Takasugi, S., Osawa,

S., Hashiba, K., and Perales, K.: “Temperature Profiling/Bottom Pressure

Monitoring System Using Optical Fiber and Capillary Tube – Field Test in a

Geothermal Well,” 1995 Annual Meeting Geothermal Research Society, Japan.

2.

Orrell, P., and Harjes, B.:

“Borehole Temperature Measurements using Distributed Fibre Optic Sensing,”

International Institute for Geothermal Research (1993).

3.

Karakan, S., Kutlik, R., and

Kluth, E.: “Field Trial to Test Fiber Optic Sensors for Downhole Temperature

and Pressure Measurements West Coalinga Field, California, SPE 35685 (1996).

Pressure Sensing:

Multi-point fiber optic pressure

sensing can be used for permanent monitoring operations to discern reservoir

pressure and zonal contributions. Some

typical examples include evaluating fractured systems, measurement of drawdown,

assessment of skin, reservoir heterogeneity, permeability, completion

efficiency, drainage and front radius inferences, developing performance curves

…

Principles of Operation:

Pressure is measured using a

self-referencing optical technique. The

system detects small changes in distance that occur between two points in a

ceramic pressure head when the pressure is varied. The micron (10-6 m) scale gap in the sensor head is monitored using

optical interference patterns to provide accurate pressure readings. The ceramic sensor is designed

to be stable at elevated temperatures over extended time periods. Sensor temperature compensation

is achieved by using concurrent Distributed Temperature measurement. The

fiber optic pressure sensor is protected by US Patents 5446280, 5963321 and

6069686.

All of the necessary optical equipment sources and detectors are maintained at the surface away from the downhole environment. The Surface Readout Systems (SRO) is an opto-electronic assembly. It houses the light source and the photo-detectors, along with the ancillary couplers and filters. The unit has its own power supply, digital processor and data storage systems.

Laser light is transmitted to

the sensor using a cable that can contain up to 12 optical fibers. This allows up to 11 pressure sensors and a

Distributed Temperature measurement to be installed in a single well with one

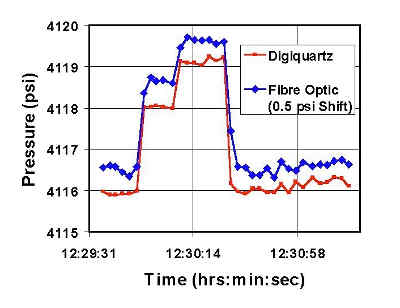

cable, if required. Figure 3 shows the

accuracy of fiber optic pressure measurement.

Figure 3. Comparison of pressures measured using fiber optics methods with those determined from a digital quartz gauge.

Specifications:

|

Operating Range |

0 to 18,000 psi in 2,000 to

6000 psi steps |

|

Accuracy |

+/- 0.035% of range |

|

Resolution |

+/- 0.05 psi |

|

Repeatability |

+/- 0.035% of range |

|

Long term drift |

<0.5 psi per year |

|

Sampling frequency |

1 second plus |

|

Maximum temperature |

175°C |

|

Temperature accuracy |

0.5°C |

|

Measurement range |

>12 km |

|

Housing Diameter |

0.625 inches |

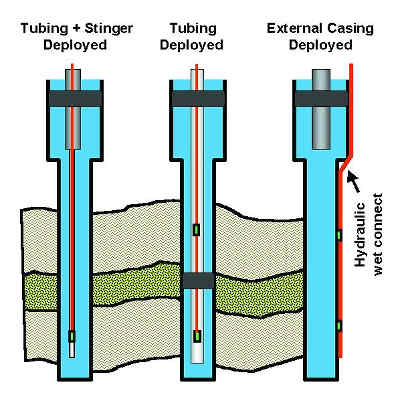

Implementation:

In its

simplest form the pressure sensor can be deployed like a conventional

electronic gauge. Initial designs are suitable for installation outside 4 1 /2 "

tubing located inside 7" casing.

Several Sensa pressure sensors can be installed on the same completion

and used to monitor the pressure in different producing zones or the pressure

distribution along a horizontal section. A full range of accessories has

been developed to allow the deployment of sensors in different well designs.

These include wellhead adapters and penetrators, cables, packer penetrator kits

and downhole connectors.

Figure 4. Pressure Gauge Deployment.

Armored cables can contain up to

18 individual optic fibers. These

cables are rated up to 10,000 psi working pressure and 150oC.

Continuous lengths up to 10 km are available in various alloys to suit the

environment.

The pressure sensor can be

deployed like a conventional electronic pressure gauge. The system can be installed outside

4.5" tubing inside 7" casing.

Several fibre optic pressure sensors can be installed on the same

completion and can be used to monitor the pressure in different injection zones

or the pressure distribution along a horizontal section.

The pressure gauge can be installed

either above or below the packer and can be configured to measure either the

tubing or annulus pressure, as required.

Two pressure gauges mounted 10 meters apart can be used to monitor

producing fluid density. Figure 5 shows

a typical installation.

If required, several gauges can

be installed in the same well using either a cable or control line

implementation.

Figure 5. Optical connectors, packer and the pressure-sensing component.

The pressure sensor has

advantages for permanent well monitoring operations. For example:

·

Downhole electronics are not required and reliability is

high. There is high accuracy,

resolution and stability for continuous monitoring and transient analysis.

·

Up to 11 pressure and distributed temperature measurements

can be configured on one multi-cable.

·

The compact OD sensor design is suitable for slimhole

operations.

·

Surface readout allows additional channels to be added at

any time

·

Standard cable design incorporates the Distributed

Temperature Sensor.

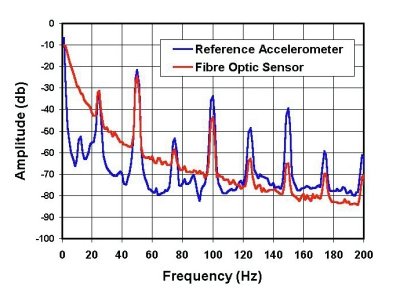

Acoustic Flow Sensor

Acoustics sensing measures flow,

determines changes in fluid phase and detects sand production (Figure 6). Optical acoustic monitoring is a

new tool for permanent monitoring. Cutting edge fibre optic technology monitors

near-field acoustic noise and vibration, providing real time data on downhole

flow and sand production.

Applications could include measuring flow rate, discerning flow

type/regime, monitoring pump condition, leak detection, and sand production

monitoring …

Figure 6. Comparison of acoustic and vibration sensor response mounted on an ESP monitor.

The

acoustic flow sensor is a permanent, fiber optic sensing system that can be

installed at several points along the producing interval to give an inflow

profile of single phase oil, water, gas and sand. Measurement of near-field acoustic noise and vibration is

achieved using fibre optic time domain reflectrometric interferometry

technology developed by Thompson Marconi Sonar Ltd. and available exclusively

from Sensa Ltd. for use in the oil and gas industry.

The

sensor consists of a wound length of fibre using patented techniques,

encapsulated in a pressure housing which is acoustically mounted at customer

defined locations on the completion (Figure 7). The chamber is acoustically coupled to the completion at a

customer-defined location within the well. This can either be externally

on tubing, measuring flow inside, or mounted on a “stinger” inside the

producing zone measuring external flow.

The sensors are interrogated with highly coherent pulses of laser light. The returned signals, containing the

acoustic data, are demodulated in the Opto-Electronics surface unit and

recorded. The data are then processed

for significant events and stored for offline processing/ trending if required.

Figure 7. Deployment schematic.

Specifications

are shown in the following table.

|

Frequency

range |

5-10,000

Hz |

|

Dynamic

range |

80

db |

|

Sensitivity |

30

mV/ms2 |

|

Frequency

resolution |

1/20

Hz |

|

Maximum

temperature |

150°C |

|

Maximum

pressure |

20,000

psi |

|

Time

increments |

15

minutes plus |

|

Operating

range |

20

km |

Features of this system include:

·

Requires no downhole

electronics ensuring high reliability

·

High temperature capability (up

to 150oC)

·

Fibre optic sensors are immune to electromagnetic

interference (EMI) and are thus unaffected by ESP motor electrical noise

·

Continuous data acquisition –

without well intervention

·

A single sensor can be used for

flow rate, flow regime and sand detection

·

An array of sensors can be

installed on a single optical fibre

·

Sensor arrays can be run

together with Sensa fibre optic pressure and distributed temperature systems

using one fibre optic multi-cable.

Deployment:

Acoustic sensors can be mounted

on an ESP pump or motor to monitor performance. They can also be installed at

any point along the production tubing to monitor flow or sand production e.g.

between producing zones. Mounting the

Sensa Acoustic Sensor on an ESP pump or motor will allow the low frequency

vibration spectrum to be monitored all the time. Increases in vibration will

indicate deterioration in the efficiency of the pump or motor and allow

appropriate decisions to be made about optimization or replacement.

Principles:

McKinley and Bower (SPE 6784)

demonstrated that acoustic signals in a borehole are proportional to the flow

rate and pressure drop along the flowing section. Thus a permanently installed

acoustic sensor can indicate flow rate changes in flow over time. Van der Spek (SPE 50640)

demonstrated that acoustic measurements could also be used to successfully identify

flow regime using neural net technology.

Sand production causes high

frequency noise due to the sand particles impinging on the pipe walls.

Conventionally, acoustic sand detectors are mounted on pipe bends at the

surface. The

Sensa Acoustic Sensor provides the opportunity to install a sensor device above

each producing zone - thus identifying which is the source of sand production.

References:

1.

Van der Spek, A (1998)

"Neural Net Identification Of Flow Regime Using Band Spectra Of Flow

Generated Sound," SPE 50640,SPE, The Hague, The Netherlands.

2.

Mckinley, R.M., Bower, F.M.

& Rumble, R.C.: "The Structure And Interpretation Of Noise From Flow

Behind Cemented Casing," SPE 6784, SPE-AIME San Antonio, Texas

(1973).

Example Field Applications

Fiber optic-distributed temperature sensors

installed using the Sensor Highway conduit can supercede coiled tubing-conveyed

production logs. Two Wytch Farm wells

(onshore/offshore development on the southern English coast) have been

completed with fiber optic sensors. The

purpose of the sensors is to monitor downhole electrical submersible pumps and

well performance. One of the wells is a

relatively simple vertical completion with an ESP, while the other is a more

complex horizontal dual-purpose well.

The distributed temperature data from the simple

ESP completion was effective in describing the operating condition of the ESP

pump.

In the horizontal well's case, there are

encouraging indications that inflow along the horizontal section is

observed. This dual-purpose

injector/producer has a crossflow sub to allow produced water reinjection below

the oil/water boundary while crude is produced along a long horizontal section.

Conventional PLTs cannot be run in this well because the ESP requires a shroud

and there is no logging bypass. In

addition, the cross-flow sub is not full bore.

The

BP-Amoco Wytch Farm site uses ERD wells to reach the reservoir located under

Poole Harbour and the English Channel.

It was desirable to monitor the complete

temperature profiles of the wells and in particular the producing zones - to

determine which areas of the reservoir are producing and to identify any

production problems, such as water breakthrough.

The

Sherwood reservoir extends approximately 15 km under Poole Harbour and the English

Channel. Some of the wells have been

drilled out horizontally with a measured depth of over 10 km and a vertical

depth of ~1600 meters. Artificial lift

is used because of low reservoir pressure - generally by downhole electrical

submersible pumps (ESPs).

Following

a successful test to evaluate both ease of installation of the Sensa system in

well K-7 in 1997, Sensa’s real-time, fiber optic distributed temperature

monitoring systems were installed in extended reach development (ERD) wells –

M-12 and M-17 in 1998 and 1999 respectively.

Producing

9,500 barrels per day, M-12 is a dual-purpose completion – where oil is

produced and water is injected into lower zones to maintain reservoir

pressure. While this type of completion

cannot be logged using conventional production logging techniques the Sensa

system proved to be relatively simple to integrate into the completion. The fibre optic control line was attached to

the outside of the 4" production tubing, with a hydraulic ‘wet connect’

supplied by Baker Oil Tools to allow disconnection of the lower completion for

ESP maintenance, if required. With a

measured depth of 5,100 meters and a vertical depth of 1,500 meters, a total of

10,500 meters of optical fibre were installed in the well to provide temperature

data points at one-meter intervals over the whole length of the well.

M-17

produces approximately 5,000 barrels a day by ESP pump and is not used for

water injection. In this case, the

fibre optic control line was installed across the reservoir attached to a 2 7/8” tubing ‘stinger’ below

the ESP.

The

relative proximity of the wellheads for both M12 and M17, meant that both wells

could be monitored using a single multiplexed processor, located at a central

location.

Following

the installation of Sensa instrumentation in M-17, temperature profiles of both

wells have been monitored with 100% reliability. For the first year following

installation in M-12, the well was monitored during shut-ins or multi-rate well

tests.

Ongoing

reporting of real-time monitoring data from M-17 provided a continuous picture

of the reservoir temperature changes with time. Recording a significant temperature drop at the toe of the well,

the Sensa system identified a zone of cold injection water breakthrough,

believed to be from a nearby seawater injector.

Analysis

of M-17 data using a thermal wellbore simulator identified the majority of

production was at the heel of the well, highlighting a possible fault. The simulator allows a variety of producing

scenarios to be examined so the most likely solution – which fits both with the

observed temperature response and other reservoir and production data – can be

determined. By matching the thermal

simulator model to the recorded temperature data, producing zones can be identified

and production estimates obtained. Instant Information.

A key

issue with M-12 was the ability of the Sensa system to quickly identify water

production from behind the casing of a cemented off water zone. Conventional

production logging techniques may have highlighted the problem if it had been

possible to log this well. However,

this information would have only been acquired after an expensive logging run

had been completed and the results interpreted. Instant access to complete thermal well profiles allows for a

more proactive approach to reservoir and production monitoring.

Data

from both wells are recorded continuously 24 hours a day and downloaded once a

week remotely by telephone line to the Sensa head office in Andover. Daily checks are made on the well profile

and BP-Amoco is notified immediately if a significant change is observed. Detailed data interpretation is carried out

by Sensa and discussed with Wytch Farm reservoir and production engineers on a

monthly basis. Sensa uses Landmark

Wellcat™ software to produce a thermal model of the well based on multi-zone

flow. Comparing the thermal response of

flowing and non-flowing zones to the measured data gives valuable information

on interval production. Data is

supplied to BP-Amoco both as DTS.bin files and summarized EXCEL™ spreadsheets.

Baker

Hughes substantially provided a completion, - an evolution from the earlier

Wytch Farm M10 well completion design – for a well with >6,000 meters md,

producing oil over about 1,000 meters.

It was desired to determine whether continuous distributed temperature

measurements along the producing interval could be used to describe the

production inflow response along the perforated section.

This was a one-trip completion using a hydraulic

wet connect system (Baker Oil Tools) to permit installation of the sensors

below the ESP. A Baker JMZX packer was

used as the linear tieback packer. The

large bore allowed running the dual 1/4-in. conduits and clamping them to the 4

1/2-in. tubing running along the producing interval and run to a turnaround sub

that was set above the lower packer - a Baker SABL-3 Hydro set design. This installed the two 1/4-in steel conduits

in the pre-perforated horizontal producing section.

The wet-connect tool was operated during the

completion phase to enable the completion space-out to be performed. Fluid pressure in the 1/4-in, conduit was

increased to allow the interlock function to be disabled and the tool was

disconnected, parting the string below the shrouded ESP. After spaceout, the tool was reconnected and

the conduit was successfully pressure tested.

A completed loop of 1/4-inch conduit, 10,000 meters

long, was installed in a complex horizontal well, including a 1,000-meter

horizontal section where the conduit was clamped to the outside of 4 1/2-in.

tubing inside a 7-in. liner. The next

step was to install 10,000 meters of optical fiber using fluid drag into the

1/4-in conduit loop!

Initially, the fiber wouldn’t deploy into the

conduit. After the conduit was flushed

with isopropanol (to remove hydraulic oil), the fiber went through without

difficulty. Initially, a 6,000-meter-length fiber was installed to operate in

single-ended mode. Later, this will be replaced by a 10,000-meter fiber loop.

Distributed

temperature data is being gathered in a well from which real-time well

performance data would otherwise have been unattainable. Early results suggest the temperature

profile along the 1,000-meter horizontal section is not linear and that there

are regions of greater or lesser temperatures.

Fiber

optics can be used to manage intelligent well operations. Through controlling the channeling of

hydraulics with fiber optic switches, it is possible to operate an array of

tools located within the wellbore from the surface. Numerous fiber optic

actuators are available that are capable of exerting large forces, with

sufficient displacements ranging from several micrometers to a few millimeters.

Piezoelectric actuators have been adopted widely.

Their main advantages are generation of large forces, high movement resolution,

high dynamics and the potential for miniaturization. It should be possible to

operate certain hydraulic devices (such as safety valves and sliding sleeves),

to optimize gas lift valves and to set packers using these systems.

Some Other

Applications

Flow Rate Measurement

Using a fiber optic distributed temperature measurement

system, changes in temperature with time can be correlated with fluid

flow. Thermal profiles can be

determined in a vertical well with a single

zone, a vertical well with multiple

zones, high rate horizontals and low rate horizontal wells.

Vertical Well

Single Injection/Production Zone

The temperature profile in a

vertical (or deviated) well depends on the virgin geothermal gradient, the

injected/produced/formation fluid, the thermal properties of the formation, the

mass flow rate and the injection time.

Characteristically the temperature profile above any producing/injecting

interval becomes asymptotic to a line that is parallel to the geothermal

gradient. This temperature profile

changes with flow rate. This is shown

schematically in Figure 8. Injection

measurements for injection may be more subtle and the most diagnostic

information may come from the nature of thermal recovery in the wellbore when

the well is shut-in.

Thermal logging has been

frequently used for modeling the vertical extent of hydraulic fractures that

have been placed for stimulation purposes.

Certain precautions are necessary.

First, if the fracture deviates from the wellbore, even by a relatively

small amount, the full vertical extent may not be evident. Often, temperature logging after hydraulic

fracturing only shows the perforated interval.

In addition, in hydraulic fracturing for stimulation dead fluid in the

rat hole sometimes masks downward growth (may or may not be an issue for an

injector).

Figure 8. This shows a single production zone in a vertical well and how the temperature profile deviates from the virgin temperature profile with an increased rate of production. It is more difficult to determine definitive inflow for injection situations because the wellbore temperature is dominated by the nominally constant injection fluid temperature. Excursions may be evident due to changes in formation temperature and the rate at which the temperature recovers if the well is shut-in (analogous to temperature logging for mapping hydraulic fracture extent).

Vertical Well Multiple

Producing Zones Thermal Profile

In a production scenario, where flow is coming from more than one zone, additional production from a higher interval will enter the wellbore at a lower temperature. The contribution from each zone can be estimated from the drop in the overall fluid temperature as the two fluid streams combine. Again, flow distribution in injectors may be less apparent from thermal variations although the same concepts apply (Figure 9).

Figure 9. This shows two production zones in a vertical well and how the temperature profile deviates from the virgin temperature profile with an increased rate of production. It is more difficult to determine definitive inflow for injection situations because the wellbore temperature is dominated by the nominally constant injection fluid temperature. Excursions may be evident due to changes in formation temperature and the rate at which the temperature recovers if the well is shut-in (analogous to temperature logging for mapping hydraulic fracture extent).

Horizontal

Wells - High Flow Rate

During production, as oil flows along a horizontal well the

pressure drop causes Joule-Thompson warming of the fluid. The reverse can be true for gas. This temperature is at least partially a

function of the flow rate. Given

sufficient flow, a temperature increase (or decrease depending on the fluid

properties) of over one degree Centigrade may be generated along the horizontal

section. This can readily be

detected. You can imagine applying

similar considerations (differential temperature along the length of the well

depending on how the flow is partitioned into various zones) for

injectors. Figure 10 is an example for

a production scenario. If the rate is

low, changes in temperature are smaller and passive thermal measurements may

not be adequate. Sensor technology has

overcome this (see low rate horizontal wells).

Figure 10. Inflow and outflow can be discerned by judicious monitoring of the temperature profile in high rate horizontal wells. Modest temperature variations can be discerned. If the rate is not high enough, it may be necessary to “help” the sensors (see low rate horizontal wells, below).

Horizontal

Wells - Low Flow Rate

In low rate horizontal wells,

the measured temperature will not vary adequately as a function of flow. To overcome this, Sensa has developed a

method of creating short thermal transients in the flowing fluid using their

patented Flo-Trak™ system. This enables

the velocity of the flowing fluid to be measured at each Flo-Trak™ element

location by tracking a slug of cooled fluid, created by the Flo-Trak™ system,

with the distributed temperature system (refer to Figure 11).

Figure 11. For low rate wells, measurement is not strictly a passive activity. Thermal transients are induced and monitored.

How

is Flow Rate Determined?

The Flo-Trak™ Fluid Velocity Tracking System uses a pre-installed Sensa Distributed Temperature System and heating coils to accurately track the velocity of single-phase fluid at low flow rates at specified points downhole.

The

Flo-Trak TM Fluid Velocity Tracking System* uses a pre-installed

Sensa Distributed Temperature System and heating coils to accurately track the

velocity of single phase fluid at low flow rates at specified points downhole.

Measurement of fluid velocity is achieved by creating a transient temperature

anomaly in the produced fluid with a heating coil and tracking this anomaly as

it moves up the well using a sensitive fibre optic

This

records the fluid temperature every meter along the fiber at sampling

frequencies down to 1 Hz. Localized

heating is achieved from the friction of high-pressure nitrogen gas being

pumped through a small diameter coil acting as a counter-flow heat

exchanger. Delivery of the gas to the

coil is through a pre-installed control line allowing the coil to be actuated

at any time from the surface.

Distributed temperature is measured by sending a pulse of laser light

down the pre-installed optical fibre.

Molecular vibration, which is directly related to temperature, creates

weak reflected signals. The reflected

signal is detected in the surface read-out unit and is converted to values of

temperature at 1-meter intervals along the fibre and well.

Some

of the system features include:

·

Simple sensor design requires no downhole electronics -ensuring high

reliability

·

Can be installed to measure low

flow rates near the toe of horizontal wells

·

Can be installed on either side

of laterals in multi-lateral completions to define lateral contribution

·

Can be installed and used with

viscous fluids

·

Will measure fluid velocity in

either direction

·

Can be actuated at any time

from the surface (with a DTS and Nitrogen unit) to monitor flow as required

The

temperature anomaly produced by the heating coil is tracked up the well using

the fibre optic Distributed Temperature System once the heating coil is switched

off. The track of the anomaly with time versus depth gives the velocity of the

fluid.

It has

been manufactured under license from British Telecommunications plc and is the

property of Sensor Highway Ltd. Sensor.

Performance of Gas Lift Mandrels

The distributed temperature system can be used to monitor the performance of the wells Gas Lift Mandrels (GLM's). The Joule Thompson cooling effect of gas blowing through the mandrel identifies its location and cools the producing fluid, giving a qualitative indication of the mandrels efficiency. A mandrel that is slugging gas, rather than operating normally, would be readily identified using time dependant thermal monitoring.

Artificial lift is used in many fields to overcome the

effective hydrostatic head on the reservoir and so allow the oil to flow to

surface. Artificial lift involves the input of energy through gas injection;

electric power to ESPs or PCP's and improvements in the efficiency of these

methods can readily improve incremental oil production. Sensa provides downhole sensors for

performance monitoring of these systems.

Sensa’s distributed temperature

system can be used to control injection pressures according to the lifting

efficiency required.

Sensa reported that fibre optic real-time monitoring would be

(if it has not already) installed to optimize inflow performance of Shell

Expro's gas lifted oil wells in the North Sea.

Background

With

the ultimate aim of improving both the management and performance of well

inflow, Shell’s initial trial set out to assess Sensa’s fibre optic distributed

temperature system for its suitability to North Sea operations. The first well

to be monitored was a gas-lifted offshore well.

“Test

results to date have substantiated the Sensa technology claims and now Shell

Expro is planning to use the system to monitor inflow across the

reservoir.”

Initial

trials were carried out on Shell Expro’s Tern well TA-27, a 10,500 ft deep gas

lift well - completed with 9 5 /8" casing and 5 1/2" inch tubing. Gas lift valves were set at

1,235, 2,190 and 2,825 meters.

Monitoring gas lift valves has to date only been achievable in wells

equipped with single point temperature probes set around the valve itself or by

conventional logging methods. The

distributed temperature system provided a complete thermal profile of the well

and identifies the correct operation of the appropriate gas lift valve by

monitoring the change in temperature of the produced fluid as it passes the gas

lift valve.

The

first stage of testing was to demonstrate the Sensa technique for pumping

optical fiber into a hydraulic conduit (control line) to just above the

packer. Serving as both a sensor and a

transmission system, the fiber provides temperature readings at one-meter

intervals from the surface to below the lowest gas lift mandrel. The temperature profiling system was able to

monitor the well during critical operations such as start-up and unloading as

well as monitoring the gas lifting system throughout its operation.

Results:

Tern

well TA-27 was successfully installed with Sensa’s distributed temperature

system and has been monitoring temperature on a continuous basis since 28 April

2000. The Sensa system can identify

critical temperatures throughout the well. Analysis and interpretation of the

continuously acquired data will allow completion design to be modified for

future wells to be completed at lower costs and greater safety. For example, the continuous acquisition of

temperature data will enable hydrate and wax formation to be proactively

inhibited and so allow subsurface safety valves (SSSV) to be located as near to

the surface as possible. This will

translate into significant cost savings brought about by the reduction in

casing sizes for the completion and possibly a simpler SSSV design.

Sensa’s

temperature measurements also highlight the proximity of other wells and can

indicate where interference from different wells is affecting production.

By

pin-pointing well inflow rates, distributed temperature measurements can

identify any early signs of scale build-up, enabling Shell Expro to put

preventative maintenance in place to preempt problems such as blocked safety

valves.

Distributed

temperature data are recorded continuously on the Tern platform, 24 hours a day

and distributed to Shell Expro and Sensa via an Internet link for storage and

interpretation. Daily checks are made

on the well profile by both companies – providing an immediate indication of

any significant change in the well’s performance. Detailed data interpretations are produced and discussed on a

monthly basis.

To

verify the quality of Sensa’s data, Shell Expro has also carried out tests and

comparisons with known geothermal temperatures – proving the reliability of the

new technique. Comparing the thermal response of flowing and non-flowing zones

to measured data provided by Sensa’s interpretation package – provided by

Landmark Wellcat™ – gives relevant information on interval production.

Shell U.K. Exploration and Production (Shell Expro)

operates in the U.K. sector of the North Sea on behalf of Shell, Esso and other

co-venturers.

Is Crossflow Occurring?

Distributed temperature monitoring allows identification of

crossflowing zones (which have a similar thermal response to flow outside the

casing) identifying which reservoir intervals have higher or lower pressures

after periods of production.

A distributed temperature system can provide real-time

information as a downhole permanent distributed temperature-monitoring

system. Figure 5 shows one typical

application for determination of crossflow.

Figure 5. Temperature monitoring along the completed length can provide indications of crossflow.

Water Production

The different thermal properties of water, compared to oil,

cause a shift towards the geothermal gradient when a zone flowing oil goes wet.

If distributed temperature is being continuously monitored there will be a

change in the thermal profile at the point of water entry which will correlate

in time with the increase in water cut observed at the surface - and thus

identify the location of the water entry.

Gas Production Monitoring:

When gas is produced, the pressure drop around the well bore

will cause Joule Thompson cooling of the gas as it enters the wellbore. This can be identified from a distributed

temperature profile.

In vertical wells multiple gas entries can be recognized from

their cooling effect and the thermal response can be analyzed to give an

indication of contribution by zone.

Figure 6 is a schematic of this behavior.

Figure 6. You can use deviations from a baseline thermal profile to determine entrance of gas in one or more zones in a producer. Changes in the relative contribution of the produced fluids will be reflected in changes in the observed temperature profile.

Monitoring Injectors:

When water is injected into a reservoir the thermal profile

observed in the well bore is normally close to that of the injected water

surface temperature. However if the

well is shut-in for a period, the permeable zones, which have been taking the

water (colder if seawater, hotter or slightly cooler if produced water), warm back

towards the geothermal gradient at a much slower rate than those that are not

permeable.

Monitoring the warmback

temperature response when the well is shut-in will identify the permeable zones

and an estimation of the relative contribution can be made.

Fracture Identification

Through continual processing of the continuously acquired